01 Jun What makes Zoom Pro Trimming Machine Different

What makes Zoom Pro Trimming Machine Different

If you’re in the commercial market for a new trimming machine, you may have come across the Zoom Pro. This trimming machine stands out from the competition for several reasons. In this post, we’ll take a closer look at what makes the Zoom Pro trimming machine different and why it may be the right choice for your trimming needs.

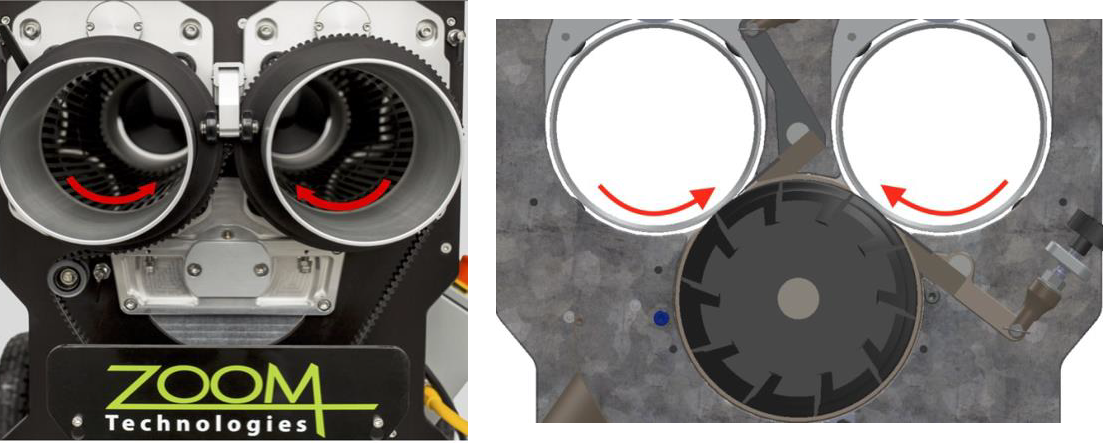

COUNTER-ROTATING DOUBLE BARREL SYSTEM

The first thing that sets the Zoom Pro apart is its counter-rotating double barrel system. The Right Barrel rotates clockwise, while the Left Barrel rotates counter- clockwise. This system creates a natural turning force to tumble the material into the center cutting zone and result in the perfect trim. At the same time, the paralleled two-barrel design increases the feeding rate and throughput more than twice than the single barrel system on the market, which greatly improve the efficiency.

ADJUSTABLE TUMBLER SPEED, TILT CONTROL AND VACUUM RATE

These features allow you to customize the trimming process to handle variable strains and different moisture condition product. You can adjust the tumbler speed to control the trimming speed. If you want a rough trim you can raise up the machine tilt and run the material through faster. When you are trimming dry and want a gentle process, you can tune down the vacuum air flow rate to reduce the suction. You decide which settings work best for your product.

EASY TO CLEAN AND MAINTAIN

Cleaning a trimming machine can be a hassle. Depending on the model of the trimming machine, disassembling the machine for cleaning may be required. This can be a time-consuming process that requires careful attention to detail to ensure that all parts are reassembled correctly. This could be time-consuming and labor-intensive. Additionally, it adds to the machine downtime which affects the efficiency especially during the harvest.

Zoom Pro is designed to be easy to clean and maintain. We use slide pins that are simple and quick to operate. All the shrouds can be removed in minutes for pressure washing the machine. Food contact parts are easy to be disassembled and accessed in minutes without using tools. To learn how to clean the Zoom Pro, watch the video here.

PROUDLY MADE IN USA

We design, test and build our equipment proudly in the USA using the best materials and components available. This allows us to respond to parts and service requests quickly, as we know downtime during harvest is not an option. The Zoom Pro comes with 5 years warranty and is 100% serviceable. We have all the spare parts stocked in USA.

To request a demo or ask more questions about the Zoom Pro, Contact Us.

Read More: Trimming on a Budget vs Investing in Quality